Granule Sugar Packaging Machine Manufacturer in China - Quality Solutions

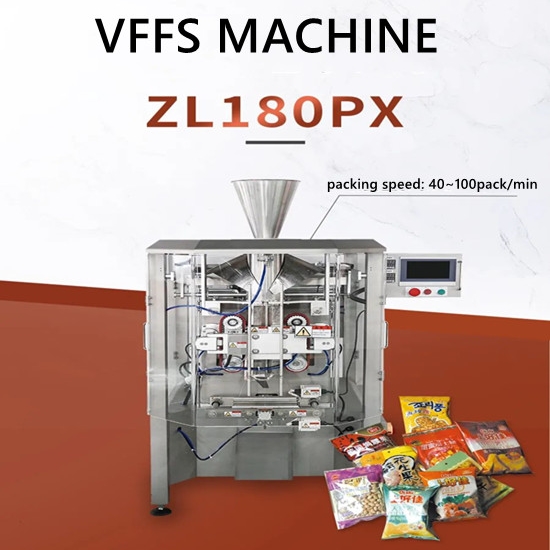

When it comes to efficiency and reliability in granule sugar production, our Granule Sugar Packaging Machine stands out. As a leading manufacturer in China, we've designed this machine to meet the unique needs of businesses like yours. With advanced technology, it ensures precise weighing and packaging, reducing waste and maximizing output. I’ve seen how it can handle various bag sizes with ease, making it perfect for both small and large-scale operations. The user-friendly interface simplifies operation, allowing your team to get up and running quickly. Plus, our commitment to quality means you can rely on this durable machine for years to come. Choosing our Granule Sugar Packaging Machine means investing in your production line's efficiency. Don't just take my word for it—let the performance speak for itself and elevate your packaging process today!

Granule Sugar Packaging Machine For the Current Year Sets the Industry Standard

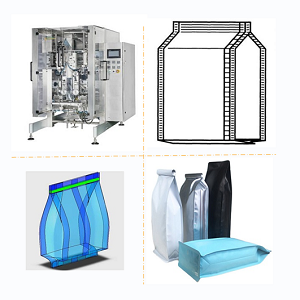

In today’s fast-paced food processing industry, the demand for efficient and reliable packaging solutions is ever-growing. Granule sugar, a staple ingredient globally, requires specialized machinery that not only ensures quality but also enhances productivity. This year, advancements in granule sugar packaging technology have set a new standard, focusing on automation, accuracy, and sustainability. Integrating cutting-edge technology with user-friendly interfaces, modern machines streamline the packaging process, reduce waste, and improve overall operational efficiency for manufacturers. Global procurement specialists are keenly aware of the importance of selecting high-performance equipment that meets their production needs. The latest granule sugar packaging machines are designed with features such as precision filling systems, versatile packaging options, and compliance with international quality standards. These innovations not only minimize human error but also ensure that products remain fresh and uncontaminated during packaging. Additionally, the incorporation of eco-friendly materials in the packaging process aligns with a growing consumer preference for sustainable practices, making these machines an attractive choice for manufacturers aiming to enhance their market appeal. Investing in advanced granule sugar packaging machinery positions companies to thrive in an increasingly competitive landscape. As industry benchmarks evolve, staying ahead means adopting the latest solutions that offer not just efficiency but also value. For procurement professionals, evaluating the performance and reliability of packaging machinery is crucial in making informed decisions. The new standard set by this year's innovative machines promises to deliver enhanced production capabilities while ensuring product integrity, ultimately driving success in the global market.

Granule Sugar Packaging Machine For the Current Year Sets the Industry Standard

| Model | Production Capacity (bags/min) | Sealing Type | Machine Weight (kg) | Energy Consumption (kW) | Dimensions (LxWxH in mm) |

|---|---|---|---|---|---|

| SGP-1000 | 25 | Heat Sealing | 150 | 2.5 | 1200 x 800 x 1800 |

| SGP-2000 | 35 | Ultrasonic | 200 | 3.0 | 1400 x 900 x 1900 |

| SGP-3000 | 40 | Pneumatic | 250 | 4.0 | 1600 x 950 x 2000 |

| SGP-4000 | 50 | Cold Sealing | 300 | 5.0 | 1800 x 1000 x 2100 |

Related Products