Wholesale Jelly Food Packaging Machine from Leading Manufacturers

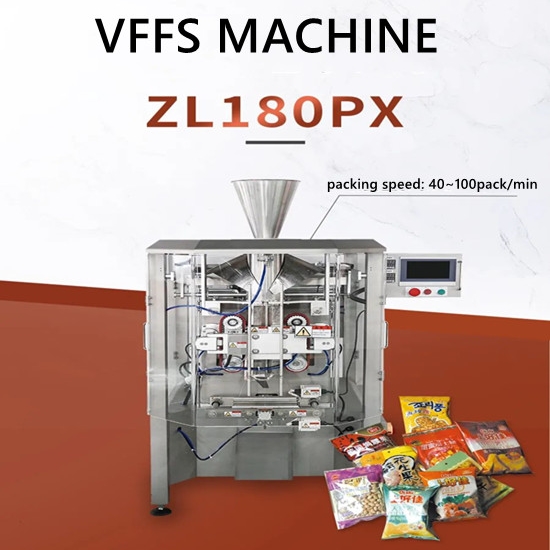

When it comes to optimizing your jelly production line, I’ve found that a reliable jelly food packaging machine is essential. This machine has been crafted with the needs of manufacturers in mind, ensuring efficiency and precision in every cycle. Whether you’re a wholesaler aiming to scale your operations or a manufacturer seeking to enhance packaging speeds, this equipment is designed to meet your demands. I’ve seen first-hand how this machine can improve workflow, minimize waste, and maintain product quality. The user-friendly interface allows for easy adjustments, making it perfect for any production size. With durable construction, it promises longevity, ensuring you get the best return on your investment. Plus, partnering with credible manufacturers means you can expect top-tier support and service. If you’re in the market for a jelly food packaging machine, this is the choice that ticks all the boxes for quality, efficiency, and reliability.

Jelly Food Packaging Machine Service Winning in 2025

In 2025, the landscape of food packaging is set to evolve dramatically, particularly in the jelly segment, where innovation and sustainability are becoming paramount. As the demand for jelly products continues to rise globally, so does the need for efficient and reliable packaging solutions. The jelly food packaging machine service is positioned to meet these challenges head-on, ensuring that manufacturers can maintain high standards of quality while also enhancing productivity. With advancements in technology, modern jelly packaging machines are equipped with features that optimize the entire packaging process. Automation plays a crucial role, reducing labor costs and minimizing human error. Moreover, these machines are designed to use eco-friendly materials, aligning with the growing consumer preference for sustainable products. By investing in advanced packaging technology, manufacturers can not only improve operational efficiency but also appeal to environmentally-conscious consumers. As we look toward 2025 and beyond, the focus on customization and flexibility in packaging solutions will be vital. Buyers are increasingly seeking machinery that can adapt to various product shapes and sizes, enabling them to cater to diverse market demands. The jelly food packaging machine service will thus become an essential partner for businesses keen on enhancing their market competitiveness while ensuring that they remain ahead in sustainability efforts.

Jelly Food Packaging Machine Service Winning in 2025

| Feature | Description | Impact on Market | Technology Level |

|---|---|---|---|

| Speed | Can package up to 1000 units per hour | Increased efficiency for manufacturers | Advanced |

| Automation | Fully automated with minimal human intervention | Reduced labor costs | High |

| Flexibility | Can handle various jelly sizes and shapes | Attract a wider range of customers | Moderate |

| Energy Efficiency | Uses 30% less energy compared to previous models | Lower operational costs | High |

| Smart Technology | Integrated IoT for real-time monitoring | Improved maintenance and uptime | Cutting-edge |

Related Products