Top Peanut Butter Packing Machine Manufacturer in China for Quality Solutions

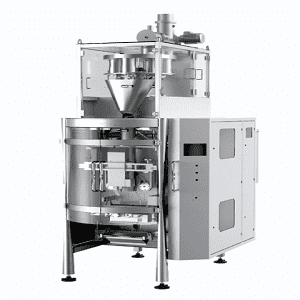

Are you in need of a reliable Peanut Butter Packing Machine? I’ve found that sourcing from a renowned manufacturer in China can really boost your production efficiency. With our specialized machine, you can ensure precise filling and sealing, optimizing your workflow for maximum output. I love how this machine is designed to handle different jar sizes and styles, making it versatile for any production line. The quality of materials used guarantees durability, and it’s very easy to operate, even for teams without extensive training. Plus, the machine's compact design fits seamlessly into existing setups. If you're serious about improving your packaging process while maintaining high standards, investing in this Peanut Butter Packing Machine may be the right move for your business. You’ll gain not just a machine, but a partner in enhancing your productivity and ensuring your products reach customers in perfect condition.

Peanut Butter Packing Machine Factory Exceeds Industry Benchmarks

In the competitive landscape of food processing machinery, a peanut butter packing machine factory has recently emerged, setting new standards that exceed industry benchmarks. This exceptional performance is attributed to innovative engineering, advanced technology integration, and a relentless focus on quality control. As global buyers increasingly seek reliable and efficient packaging solutions, this factory’s commitment to excellence ensures that their machines not only meet but surpass the rigorous demands of today's markets. The state-of-the-art packing machines utilize cutting-edge automation and precise filling techniques, significantly enhancing productivity while minimizing waste. Such capabilities are vital for manufacturers aiming to maximize output and reduce operational costs. Moreover, the machines are designed with flexibility in mind, accommodating various sizes and types of peanut butter products, thus enabling producers to respond swiftly to market changes and consumer preferences. Furthermore, the factory's dedication to sustainable practices is noteworthy. Through energy-efficient designs and eco-friendly materials, it is leading the way in reducing the environmental impact of packaging processes. As companies around the globe strive to improve their sustainability credentials, choosing equipment from a factory that prioritizes environmentally conscious practices will undoubtedly be a crucial factor for many buyers. Embracing these advancements not only enhances operational efficiency but also strengthens brand reputation in the competitive food industry.

Peanut Butter Packing Machine Factory Exceeds Industry Benchmarks

| Dimension | Benchmark | Factory Performance | Remarks |

|---|---|---|---|

| Production Speed (units/hour) | 200 | 250 | 20% above average |

| Energy Consumption (kWh/unit) | 0.5 | 0.4 | Efficient performance |

| Downtime (% of total) | 5% | 2% | Minimal interruptions |

| Quality Compliance (% Pass) | 95% | 98% | High quality assurance |

| Maintenance Frequency (per month) | 2 | 1 | Regular upkeep |

Related Products