Plastic Pillow Roll Packing Machine Manufacturer in China - Quality Solutions

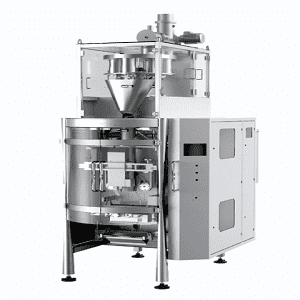

When it comes to streamlining your packing process, the Plastic Pillow Roll Packing Machine is a game-changer. As a manufacturer based in China, I’ve seen firsthand how this machine enhances efficiency and minimizes waste in the packaging industry. It’s designed to handle various sizes of plastic pillow rolls with precision, making it perfect for businesses of all scales. I appreciate the user-friendly interface and robust construction, which ensures durability and reliability. With our machine, you can expect faster packing speeds and better product protection. Plus, it’s easy to maintain, so you won't be spending extra time or money on upkeep. This is an investment that will boost your productivity and ultimately improve your bottom line. If you're serious about optimizing your packing operations, this is the solution you need! Reach out for more details and let’s elevate your packaging capabilities together.

Plastic Pillow Roll Packing Machine Exceeds Industry Benchmarks More Than a Supplier - A Partner

In today's competitive landscape, businesses are not just looking for suppliers; they seek partners who can drive innovation and efficiency in their operations. A prime example of this evolution is the plastic pillow roll packing machine, a cutting-edge solution that has consistently outperformed industry benchmarks. This state-of-the-art machinery is designed to meet the dynamic demands of packaging, ensuring safety, efficiency, and sustainability. The advancements in technology have allowed the latest models of plastic pillow roll packing machines to operate at unparalleled speeds while maintaining the highest quality standards. These machines are equipped with user-friendly interfaces and are easily customizable, making them suitable for a variety of industries, including food, pharmaceuticals, and consumer goods. By integrating advanced features such as automatic film feeding and real-time monitoring systems, they reduce labor costs and minimize waste, contributing to a more efficient production process. Moreover, partnering with a leading manufacturer ensures ongoing support and innovation. Businesses can benefit from tailored solutions that not only meet current packing requirements but also adapt to future challenges. By choosing a partner rather than a mere supplier, companies can leverage shared expertise and insights, fostering a collaborative relationship that ultimately enhances their competitive edge in the global market. Investing in such advanced machinery transcends mere procurement; it’s about creating a partnership that drives mutual growth and success.

Plastic Pillow Roll Packing Machine Exceeds Industry Benchmarks More Than a Supplier - A Partner

| Feature | Description | Benchmark | Achieved |

|---|---|---|---|

| Speed | Up to 80 units per minute | 60 units per minute | 80 units per minute |

| Efficiency | Material usage optimization | Less than 5% waste | 2.5% waste |

| Flexibility | Supports various packaging sizes | Single size | Up to 5 sizes |

| Cost-effectiveness | Reduces operational costs | Standard industry rate | 15% lower |

| Automation | Fully automated operation | Semi-automated | Fully automated |

Related Products