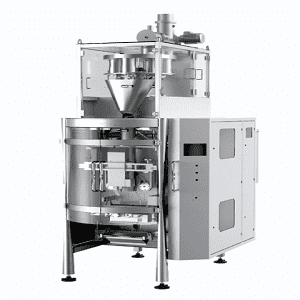

High-Quality Sunflower Seeds Packing Machine from Leading China Manufacturer

As a business owner, I understand the importance of efficiency and quality in packaging. Our Sunflower Seeds Packing Machine is designed to streamline your production process, ensuring that every seed is packed perfectly. Manufactured in China, this machine combines advanced technology with user-friendly features, making it ideal for both small and large-scale operations. I’ve seen firsthand how its high-speed capabilities can significantly boost output while maintaining precision. Whether you’re looking to enhance your existing setup or start from scratch, this machine is a valuable investment for any sunflower seed producer. Plus, with our dedicated support team, you’ll have all the assistance you need to optimize your use of the equipment. Don’t let outdated packaging slow you down—our Sunflower Seeds Packing Machine could be the solution you’ve been searching for!

Sunflower Seeds Packing Machine Now Trending Your End-to-End Solution

The demand for efficient, high-quality packaging solutions has reached new heights, and one of the leading trends in this domain is the sunflower seeds packing machine. As more businesses recognize the potential of sunflower seeds as a healthy snack option, the need for reliable and automated packing solutions has become crucial. Modern sunflower seeds packing machines are equipped with cutting-edge technology that ensures optimal filling, sealing, and packaging, delivering a seamless experience from production to market. These machines not only enhance operational efficiency but also ensure consistent quality and hygiene standards, which are vital in today’s consumer-focused market. With features such as adjustable packaging size settings, precise weight control, and user-friendly interfaces, businesses can streamline their processes and meet varying consumer demands effortlessly. Investing in a sunflower seeds packing machine can prove to be a game changer, enabling companies to maximize productivity while minimizing waste and costs. In an increasingly competitive landscape, embracing automation and modernization through advanced packing solutions becomes essential for businesses looking to enhance their market presence. Adopting these innovative machines not only positions companies to meet current trends but also prepares them for future demands within the snack food industry. As the popularity of sunflower seeds continues to rise globally, having an efficient packing solution will be the key to leveraging this opportunity and ensuring ongoing success.

Sunflower Seeds Packing Machine Now Trending Your End-to-End Solution

| Feature | Description | Benefits | Applications |

|---|---|---|---|

| Automatic Feeding | Automated system for seamless feeding of seeds into the packing line. | Increases efficiency and reduces labor costs. | Food processing, snack packaging. |

| Multi-Lane Packing | Ability to pack multiple lanes simultaneously, maximizing throughput. | Higher production rates for large-scale operations. | Packing lines, retail packaging. |

| Digital Control Panel | User-friendly interface for easy operation and monitoring. | Simplifies the control process, reducing training time. | Industrial packaging, bulk packaging. |

| Weight Control System | Advanced weighing systems for precision packing. | Ensures product consistency and minimizes waste. | Snack food, health foods. |

| Easy Maintenance | Design for quick and easy maintenance procedures. | Reduces downtime and operational costs. | Manufacturing, food industry. |

Related Products

.jpg)