Wholesale Aerosol Spray Filling Machine Manufacturers for Quality Solutions

When it comes to enhancing your production line, an aerosol spray filling machine is just what you need. I’ve seen firsthand how these machines streamline operations, ensuring precise filling and reducing waste. As a manufacturer, I know that quality and efficiency are paramount, and this equipment can deliver both, making it a top choice for wholesale buyers like you. The design of these machines allows for easy adjustments to suit different product types, from personal care to industrial applications. Plus, they help maintain a consistent output, which is vital for meeting market demands. Working with reputable manufacturers ensures you get a reliable machine that stands the test of time. Don’t miss out on the opportunity to elevate your production capabilities while saving on costs. Investing in an aerosol spray filling machine can make a significant difference in your operational efficiency and product quality. Let’s take your business to the next level!

Aerosol Spray Filling Machine Industry Giant Where Service Meets Innovation

In the dynamic world of packaging technology, aerosol spray filling machines stand as a testament to the intersection of service and innovation. As global demand grows for more efficient, reliable, and environmentally friendly packaging solutions, manufacturers have adapted by integrating advanced technologies that ensure high performance and flexibility in production lines. The latest innovations in aerosol filling machinery are focused on automating processes, improving accuracy, and minimizing waste, thereby delivering significant cost savings to businesses. The key to success in this competitive industry lies not just in the technology itself, but also in the level of service that accompanies it. Expert support, timely maintenance, and tailored solutions can elevate a company’s operational efficiency. As buyers look for reliable suppliers, the emphasis on customer-centric services becomes paramount. This means providing comprehensive training, proactive support, and responsive communication, ensuring that clients can navigate challenges seamlessly and maximize their investment. The future of the aerosol spray filling machine industry is bright, driven by continuous innovation and an unwavering commitment to customer service. As global procurement trends evolve, companies are encouraged to explore partnerships that prioritize both cutting-edge technology and responsive support. In doing so, they can not only meet today’s market demands but also position themselves strategically for future growth, enhancing their competitive edge in an ever-changing landscape.

Aerosol Spray Filling Machine Industry Giant Where Service Meets Innovation

| Characteristic | Description | Benefits | Innovative Feature |

|---|---|---|---|

| Filling Accuracy | High precision filling mechanism. | Reduced waste and improved product consistency. | Real-time monitoring sensors. |

| Operational Speed | Can fill up to 600 cans per hour. | Increased production capacity. | Automated speed adjustment technology. |

| User Interface | Touchscreen control panel with intuitive navigation. | Ease of operation for users. | Remote operation capability via smartphone. |

| Maintenance | Low maintenance design with easy access to components. | Minimized downtime and operational costs. | Predictive maintenance analytics. |

| Safety Standards | Complies with international safety regulations. | Enhanced worker safety and reduced liability. | Emergency stop systems and safety guards. |

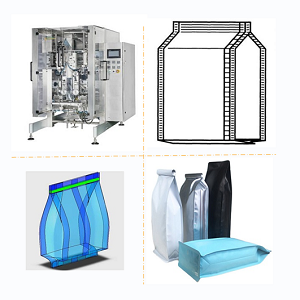

Related Products