Top China Manufacturer of Automatic Filling Machines for Your Business

As a business owner, I've seen firsthand the importance of efficiency in production. Our Automatic Filling Machine is crafted to streamline your filling process, ensuring consistency and speed that can elevate your operations. Sourced directly from reputable manufacturers in China, this machine boasts robust design tailored for various liquids, whether it’s for food, pharmaceuticals, or cosmetics. I appreciate how easy it is to operate, significantly reducing labor costs while increasing output. With customizable settings, it meets diverse production needs and adheres to strict quality standards. Plus, the durable materials used mean that maintenance is minimal and downtime is reduced. If you're looking to enhance your production line with reliable technology, our Automatic Filling Machine is a game changer. Invest in your efficiency and watch your profits grow; It’s a smart decision for any serious manufacturer!

Automatic Filling Machine Is The Best Dominates

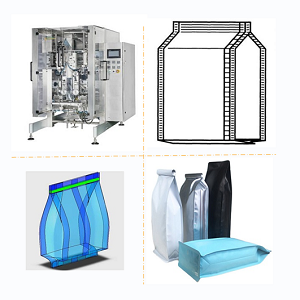

When it comes to streamlining production processes, an automatic filling machine stands out as an indispensable asset for businesses across various industries. These machines offer unparalleled efficiency, accuracy, and versatility, minimizing human error and maximizing productivity. By automating the filling process, companies can significantly reduce labor costs and increase output, making them an attractive option for global buyers looking to enhance their operational capabilities. The robust design and advanced technology of automatic filling machines enable them to handle a wide range of materials, from liquids to powders, ensuring that businesses can cater to diverse product lines without extensive downtime for recalibration. This adaptability not only helps in meeting varied consumer demands but also supports businesses in scaling operations as needed—an essential factor in today’s fast-paced market environment. Investing in an automatic filling machine is not just about enhancing efficiency; it’s also about ensuring product quality and consistency. With the ability to set precise filling parameters and monitored processes, these machines maintain high standards and compliance with industry regulations. As global procurement trends continue to shift towards automation and smart manufacturing solutions, choosing an automatic filling machine is emerging as a strategic decision that enables businesses to stay competitive and thrive in the international market.

Automatic Filling Machine Is The Best Dominates

| Model | Filling Capacity (L) | Filling Speed (bottles/min) | Power (kW) | Weight (kg) |

|---|---|---|---|---|

| AFM-500 | 500 | 40 | 3 | 150 |

| AFM-1000 | 1000 | 60 | 4 | 200 |

| AFM-2000 | 2000 | 80 | 5 | 250 |

| AFM-3000 | 3000 | 100 | 6 | 300 |

Related Products