Top China Manufacturer for Essential Oil Filling Capping Solutions

I specialize in essential oil filling and capping solutions that cater to manufacturers in China. With the growing demand for high-quality essential oils, having the right equipment is essential for efficiency and productivity. My machines are designed to ensure precise filling and secure capping, minimizing waste and maximizing your output. Each unit is customizable to meet your specific needs, whether you’re a small business just starting or a larger manufacturer looking to upgrade. I understand the importance of reliability and consistency in production, and my equipment delivers just that. With years of experience supporting businesses across various sectors, I can provide guidance and support every step of the way. Let me help you enhance your production line and elevate your essential oil offerings. It’s not just about filling bottles; it’s about providing quality products that customers love, and I’m here to make that happen for you.

Essential Oil Filling Capping Where Service Meets Innovation Your End-to-End Solution

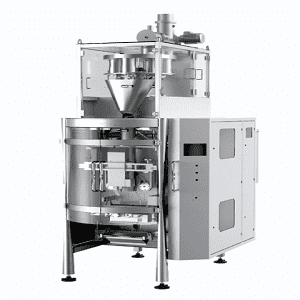

In the rapidly evolving world of essential oils, the demand for efficient and innovative filling and capping solutions has never been higher. As businesses strive to meet consumer preferences for quality and sustainability, the need for advanced machinery that can adapt to varying production scales and oil viscosities is crucial. Our comprehensive end-to-end solution harmonizes cutting-edge technology with user-friendly design, ensuring that your production line operates with maximum efficiency and minimal downtime. Our focus on innovation means that we continuously improve our filling and capping systems to accommodate the unique requirements of essential oils. Whether you're launching a new product line or scaling up production, our equipment is engineered to deliver precision and reliability. The integration of smart technology allows for real-time monitoring and adjustments, significantly enhancing productivity while maintaining the highest standards of quality control. Choosing our solution means investing in a future where service excellence meets technological advancement. We prioritize customer support and training to ensure your team can operate and maintain the equipment effectively. This commitment to service not only facilitates smooth operations but also empowers businesses to focus on what they do best—creating exquisite essential oil products that resonate in the global market. Experience the perfect blend of innovation and reliability in your production processes, driving your brand's success forward.

Essential Oil Filling Capping: Where Service Meets Innovation - Your End-to-End Solution

| Service Type | Description | Application | Benefits |

|---|---|---|---|

| Filling Services | Automatic and semi-automatic filling of essential oils into various container sizes. | Bottles, vials, and containers of different capacities. | Increased efficiency and reduced waste during the filling process. |

| Capping Services | High-quality capping solutions to secure essential oil containers. | Screw caps, dropper tops, and other sealing options. | Ensures product integrity and enhances shelf life. |

| Labeling Services | Custom labeling options with high-quality printing. | All container types requiring branding and information labels. | Improved brand recognition and regulatory compliance. |

| Quality Control | Comprehensive testing to ensure product quality and safety. | All essential oil products before distribution. | Minimized defects and enhanced customer satisfaction. |

Related Products