Top China Manufacturer of Paper Roll Wrapping Machines for Efficiency

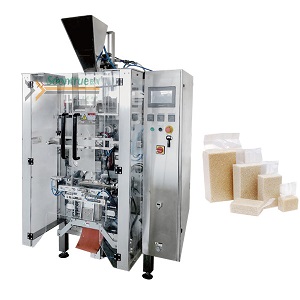

When it comes to efficient packaging solutions, I find the Paper Roll Wrapping Machine to be a game changer. This machine is specifically designed for wrapping paper rolls, ensuring enhanced protection and presentation for your products. As a manufacturer based in China, I take pride in providing high-quality machinery that meets rigorous industry standards. I've seen firsthand how this machine can streamline operations, saving you time and reducing waste. With adjustable settings, it accommodates various roll sizes, making it versatile for any business need. Plus, the user-friendly interface makes it easy for your team to operate, even in busy environments. Choosing our Paper Roll Wrapping Machine means you’re investing in durability and performance. If you're looking for a reliable partner to elevate your packaging efficiency, we’re here to support your business growth with tailored solutions that fit your requirements.

Paper Roll Wrapping Machine Is The Best Guarantees Peak Performance

When it comes to ensuring peak performance in production environments, the importance of efficient wrapping solutions cannot be overstated. The paper roll wrapping machine stands out as a premier choice for businesses looking to optimize their operations. This machine not only increases productivity but also guarantees the integrity of the product during storage and transportation. By utilizing advanced technology, these machines provide consistent results, wrapping paper rolls securely and efficiently, preventing damage and waste. With the growing demand for high-quality paper products globally, investing in an automated paper roll wrapping solution can significantly enhance operational efficiency. These machines are designed to handle various roll sizes and materials, making them versatile assets for different manufacturing processes. Moreover, features such as adjustable wrapping speeds and user-friendly interfaces enable operators to customize settings based on specific production needs, ensuring that the output meets stringent quality standards. In the competitive landscape of manufacturing, businesses must leverage innovations that align with their production goals. A paper roll wrapping machine serves as a strategic investment, promising not just reliability but also a measurable improvement in overall productivity. Adopting such technology not only satisfies customer requirements but also empowers companies to stay ahead of market trends, solidifying their position as leaders in the industry.

Paper Roll Wrapping Machine Is The Best Guarantees Peak Performance

| Feature | Description | Benefits | Specifications |

|---|---|---|---|

| Automatic Control System | Incorporates advanced sensors for performance monitoring. | Reduces human error and increases operational reliability. | Input Voltage: 220V, Power: 1.5 kW |

| High-Speed Operation | Capable of wrapping rolls at speeds up to 80 meters per minute. | Increases throughput and productivity. | Wrapping Speed: Up to 80 m/min |

| Versatile Application | Suitable for various types of paper rolls and sizes. | Adapts to changing production demands easily. | Max Roll Diameter: 500 mm, Core Diameter: 76 mm |

| User-Friendly Interface | Equipped with an intuitive touchscreen for operation. | Streamlines setup and minimizes learning curve. | Touchscreen Size: 10 inch |

| Durability | Constructed with high-quality metal for long-lasting use. | Minimizes maintenance costs and downtime. | Frame Material: Stainless Steel |

Related Products