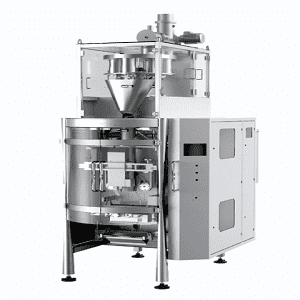

China Manufacturer of Pneumatic Liquid Water Filling Machine

When I think about efficiency and precision in liquid filling, the Pneumatic Liquid Water Filling Machine stands out. As a manufacturer based in China, we’ve invested significant expertise into designing this machine to meet the high demands of various industries. It's perfect for bottling water with accuracy, ensuring minimal waste and maximum productivity. This machine boasts easy operation and low maintenance costs, making it ideal for businesses looking to scale up their production without breaking the bank. I know how important reliability is in your production line, and our Pneumatic Liquid Water Filling Machine is built to deliver consistent performance, day in and day out. Partnering with us means you’ll have access to cutting-edge technology and a dedicated team ready to support you. Let’s enhance your filling process together with our durable and high-performance solutions!

Pneumatic Liquid Water Filling Machine Winning in 2025 From Concept to Delivery

In the rapidly evolving landscape of manufacturing and automation, the demand for efficient and innovative equipment is paramount. As we look toward 2025, the pneumatic liquid water filling machine stands out as a pivotal solution for businesses seeking to enhance their production capabilities. This advanced machinery offers exceptional speed and precision, ensuring consistent filling accuracy for various liquid types. With a sleek design and straightforward operation, it seamlessly integrates into existing production lines, minimizing downtime and maximizing output. The journey from concept to delivery of such a machine involves meticulous engineering and stringent quality controls, ensuring that it meets global industry standards. These machines are designed with user-friendly interfaces and can accommodate a wide range of bottle sizes and shapes, making them highly adaptable to different operational needs. Furthermore, their pneumatic operation not only reduces energy consumption but also decreases noise levels, making them an environmentally friendly choice for modern manufacturing. As global procurement managers seek reliable partners to meet their operational demands, investing in cutting-edge filling technology will prove advantageous. By prioritizing efficiency, safety, and sustainability, businesses can capture the competitive edge required in today’s market. Embracing innovations in machinery will not only streamline production processes but also enhance product quality, ultimately leading to increased customer satisfaction and loyalty in the years to come.

Pneumatic Liquid Water Filling Machine Winning in 2025 From Concept to Delivery

| Feature | Specification | Application | Market Trends |

|---|---|---|---|

| Filling Capacity | 2000-10000 bottles/hour | Beverage Industry | Growing demand for bottled water |

| Filling Accuracy | ±1% | Food and Beverage | Increase in quality control standards |

| Power Supply | 380V/50Hz | Industrial Use | Shift towards automation in manufacturing |

| Control System | PLC Control | Water Bottling | Enhanced precision in operations |

| Machine Dimensions | 2000mm x 1500mm x 2200mm | Manufacturing Plants | Space optimization in factories |

| Weight | 1500 kg | Production Lines | Focus on heavy-duty machinery |

Related Products