- Getting started

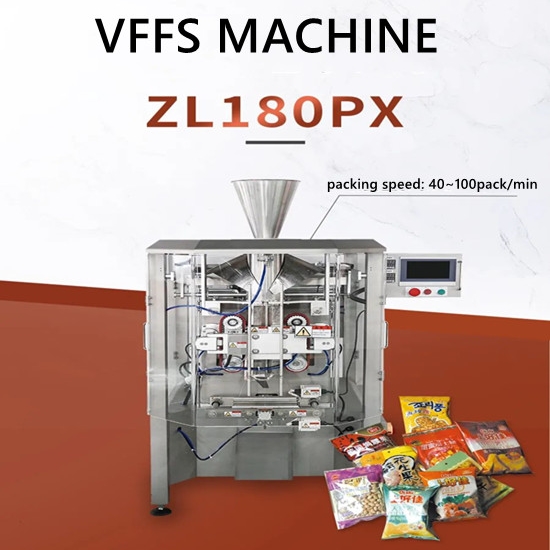

- Automatic Food Snack Packing Machine Potato Chips Vertical Multi-Function Packaging Machine

China Automatic Food Snack Packing Machine Manufacturer for Potato Chips

As a manufacturer based in China, I’m excited to offer our Automatic Food Snack Packing Machine tailored for potato chips. This vertical multi-function packaging machine is designed to streamline your production process, making it easier and more efficient. With its advanced technology, it not only maintains the freshness of chips but also ensures precise packaging to minimize waste. I understand the challenges B2B purchasers face in finding reliable, high-quality machinery, and that’s why our packing machine stands out. It’s built with durability in mind and can handle various packaging requirements, adapting to your business needs seamlessly. With user-friendly controls and maintenance that is straightforward, you will find this machine is not just an investment but a partnership in your production line. Let’s elevate your snack packaging game while ensuring your customers enjoy the best of your products!

Automatic Food Snack Packing Machine Potato Chips Vertical Multi-Function Packaging Machine Industry Leaders From Concept to Delivery

In the fast-paced snack food industry, efficiency and quality are key to staying ahead of the competition. The automatic food snack packing machine, particularly for products like potato chips, has revolutionized the way manufacturers approach packaging. This vertical multi-function packaging machine not only streamlines production but also ensures that the snacks maintain their freshness and crunch, delivering the best possible experience to consumers. With advanced technology, these machines can handle various packaging materials, sizes, and weights, offering businesses the flexibility to adapt to changing market demands. The journey from concept to delivery encompasses all the aspects of developing a reliable packing solution tailored for snacks. Starting with in-depth market analysis, manufacturers identify trends and preferences, guiding the design process. The incorporation of features such as adjustable filling volumes and sealing mechanisms enables companies to optimize their workflow and reduce waste. Additionally, automation reduces labor costs and human error, significantly increasing productivity. For global buyers, investing in high-quality packing machines represents a strategic move to enhance operational efficiency and product quality. By prioritizing reliable packaging solutions, businesses can position themselves as industry leaders, ultimately improving customer satisfaction and boosting sales. Embracing innovative technology in snack packaging not only meets current consumer demands but also sets the stage for future growth and sustainability in a competitive market.

Automatic Food Snack Packing Machine - Potato Chips Vertical Multi-Function Packaging Machine Industry Leaders From Concept to Delivery

| Feature | Description | Benefits | Application |

|---|---|---|---|

| Multi-Functionality | Capable of packing various snack types including potato chips, nuts, and granola. | Increased versatility, reducing the need for multiple machines. | Snack food manufacturers, catering businesses. |

| Vertical Design | Space-efficient design that minimizes the footprint. | Ideal for smaller production areas, maximizing workspace. | Food production facilities, supermarkets. |

| Speed | High-speed operation capable of handling large volumes. | Boosts productivity and meets high demand fluctuations. | Large-scale snack food production. |

| User-Friendly Controls | Intuitive interface for easy operation and adjustment. | Reduces training time for operators. | All levels of food manufacturing staff. |

| Quality Assurance | Built-in sensors to ensure precise packaging weight and sealing. | Enhances product quality and reduces waste. | Quality control departments within food manufacturing. |

Related Products