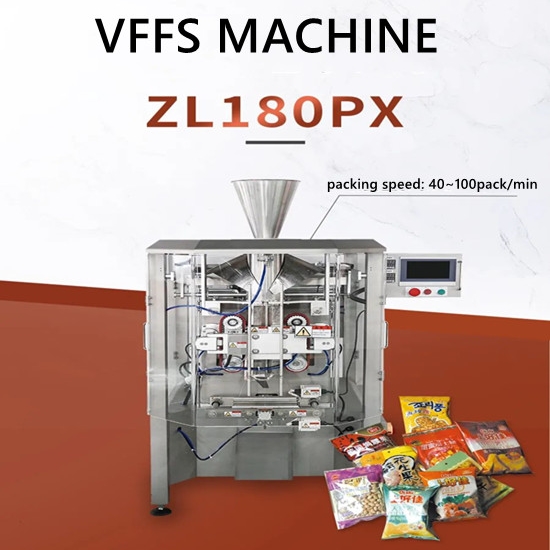

Wholesale Candy Packaging Machine Manufacturers for Efficient Solutions

When I was searching for the perfect solution for my candy business, I found the ideal Candy Packaging Machine that truly meets the demands of my production. This machine is designed for those who value efficiency and quality in packaging, making it a top choice for wholesale buyers and manufacturers alike. Its user-friendly interface and robust design help streamline operations, reducing downtime and maximizing output. I was impressed by how customizable it is, allowing for different candy types and sizes. Plus, it’s built with durability in mind, ensuring it can handle the rigors of daily use. For those in the B2B market, investing in this Candy Packaging Machine can enhance your production line and keep you competitive. Whether you’re just starting out or looking to upgrade, this machine represents a smart choice. With great performance and reliability, it truly revolutionized how I package candies, and I believe it can do the same for you.

Candy Packaging Machine For the Current Year More Than a Supplier - A Partner

In today's fast-paced and dynamic market, choosing the right partner for your candy packaging needs is more crucial than ever. A reliable candy packaging machine provider goes beyond merely supplying equipment; they become a collaborative partner dedicated to enhancing your production efficiency and product quality. With advancements in technology, today's machines offer not only high-speed packaging capabilities but also flexibility in design, allowing producers to cater to diverse consumer preferences and market trends. Investing in a cutting-edge candy packaging machine is essential for manufacturers looking to maintain a competitive edge. These machines are designed to ensure precision and consistency, reducing waste and minimizing downtime. Moreover, they can be customized to accommodate various packaging styles and materials, empowering businesses to adapt swiftly to changing market demands. A forward-thinking partner will provide comprehensive support, from machine installation to ongoing maintenance and training, ensuring systems are running at optimal performance. Furthermore, sustainability is becoming increasingly important in the candy industry. A collaborative partner will help incorporate eco-friendly practices into your packaging process, offering solutions that reduce environmental impact while appealing to environmentally conscious consumers. By leveraging advanced machinery and expert insights, producers can not only drive sales but also establish a strong brand presence in a diverse global market. Ultimately, the right partnership in candy packaging can pave the way for innovation and growth, setting manufacturers on a path toward lasting success.

| Machine Model | Production Speed (units/hr) | Power Consumption (kW) | Dimension (LxWxH, mm) | Automation Level | Material Compatibility |

|---|---|---|---|---|---|

| CandyPack 2000 | 200 | 1.5 | 1500 x 800 x 1300 | Fully Automated | Plastic, Paper |

| SweetSealer 300 | 150 | 1.2 | 1200 x 700 x 1200 | Semi-Automated | Foil, Plastic |

| ChocoPack 500 | 100 | 0.8 | 1000 x 600 x 1100 | Manual | Plastic |

| CandyWrapper 1000 | 250 | 1.0 | 1400 x 900 x 1400 | Fully Automated | Plastic, Paper, Foil |

| SugarPack 700 | 180 | 1.3 | 1300 x 750 x 1150 | Semi-Automated | Paper, Plastic |

Related Products