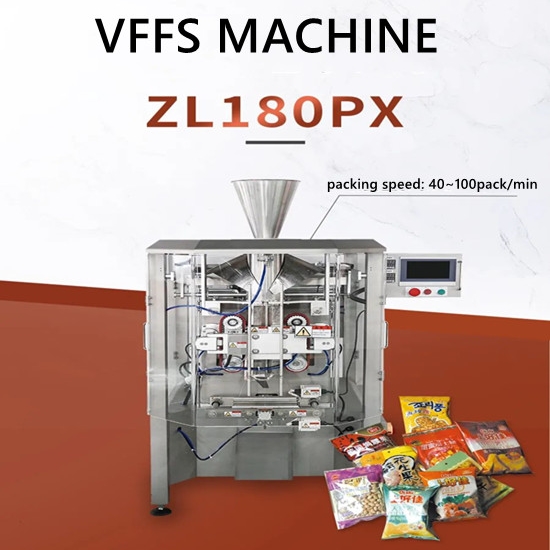

Wholesale Compress Packaging Machine Manufacturers for Efficient Solutions

As a business owner, I know the importance of efficient packaging for maximizing profits. Our Compress Packaging Machine is designed specifically for manufacturers seeking reliable, high-quality solutions for bulk packing. This robust machine simplifies the process, reducing both labor costs and material waste. Whether you're in food, pharmaceuticals, or consumer goods, this machine can streamline your operations. I often hear from clients who bought in wholesale—finding that our packaging solutions not only enhance their productivity but also improve product presentation. With customizable settings, this machine fits varied product sizes and shapes, ensuring that your items are securely packed and ready for distribution. Investing in a Compress Packaging Machine means investing in quality and efficiency, tools every manufacturer needs. Join the ranks of satisfied buyers leveraging our technology to elevate their packaging processes—your products deserve the best presentation!

Compress Packaging Machine Application Custom Solutions,

In today's fast-paced manufacturing environment, the demand for efficient and reliable packaging solutions is paramount. Compress packaging machines have emerged as vital tools in various industries, allowing businesses to enhance product protection while maximizing space and reducing shipping costs. By providing tailored solutions, manufacturers can meet the specific needs of their clients, ensuring optimal functionality and performance for their unique operational requirements. Custom compress packaging solutions enable companies to adapt to different product sizes, shapes, and materials. This flexibility not only enhances the packaging process but also ensures that products reach customers in perfect condition. With advanced technology and innovative designs, these machines can significantly streamline production lines, enabling businesses to increase their output and operational efficiency. By investing in specialized compress packaging equipment, companies can improve their competitive edge in global markets while minimizing waste and improving sustainability. Moreover, collaborating with experienced professionals in packaging technology can lead to ongoing support and maintenance strategies that further enhance machine longevity and performance. This partnership allows businesses to evolve with industry trends and customer preferences, ensuring that they remain at the forefront of packaging innovation. Embracing custom compress packaging solutions is not just about meeting current demands; it’s about building a robust foundation for future growth in an ever-evolving marketplace.

Compress Packaging Machine Application Custom Solutions

| Application | Machine Type | Material | Features | Customization Options |

|---|---|---|---|---|

| Food Packaging | Vertical Form Fill Seal | Plastic Film | High Speed, Compact Design | Size, Color, Automation Level |

| Cosmetic Packaging | Horizontal Flow Wrapper | Aluminum Foil | Tamper-Evident, Eye-Catching Design | Shape, Print Design, Size |

| Pharmaceuticals | Blister Packaging Machine | PVC, PVDC | Controlled Environment, High Accuracy | Tray Size, Automated Control |

| Beverage Packaging | Shrink Sleeve Applicator | PET, Glass | Lightweight, Eco-Friendly Options | Sleeve Size, Print Quality |

| Industrial Parts | Stretch Wrapper | Stretch Film | Heavy Duty, Weather Resistant | Film Thickness, Load Height |

Related Products

.jpg)