Top China Manufacturer of Foam Press Packing Baler Machines

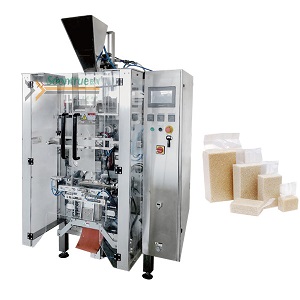

Are you in need of an efficient solution for your packing needs? Our Foam Press Packing Baler Machine stands out as a reliable choice for businesses seeking expert manufacturing from China. I’ve seen firsthand how this machine can drastically increase productivity while minimizing waste. Designed to handle various foam materials, its robust construction ensures durability and performance. With simple operation features and easy maintenance, this baler machine suits both large-scale manufacturers and smaller enterprises alike. At our facility, we take pride in delivering high-quality machinery that meets international standards. By choosing our Foam Press Packing Baler Machine, you’re investing in a product designed to optimize your packing processes and enhance your bottom line. Let me help you transform your packing operations today! Don't miss out on the opportunity to benefit from our expertise as a top manufacturer in the industry. Contact us to learn more about how our machine can meet your specific needs.

Foam Press Packing Baler Machine Now Trending Supplies the World\u2019s Top Brands

In the ever-evolving landscape of packaging solutions, the foam press packing baler machine stands out as a game-changer, capturing the attention of global brands striving for efficiency and sustainability. These machines are designed to compress foam waste into compact bales, significantly reducing storage space and optimizing logistics. As environmental awareness grows, businesses are seeking innovative ways to manage waste, and foam balers have emerged as an essential tool in their sustainability arsenal. With advanced technology and user-friendly features, modern foam press packing balers enhance operational efficiency while minimizing labor costs. They cater to various industries, from manufacturing to retail, helping brands streamline their packaging processes. Companies are increasingly turning to these machines not just for their efficiency, but also for the positive environmental impact. By utilizing balers, businesses can reduce their carbon footprint and contribute to a circular economy by ensuring that foam materials are recycled effectively. As the trend for eco-friendly solutions gains momentum, investing in foam press packing baler machines is becoming a strategic move for enterprises aiming to stay ahead of the competition. Global procurement professionals should take note of this shift and consider the long-term benefits of incorporating such technologies into their operations. By doing so, they can meet sustainability goals while also enhancing their productivity and cost-effectiveness in an increasingly environmentally conscious market.

Foam Press Packing Baler Machine Now Trending Supplies the World’s Top Brands

| Dimension | Weight (kg) | Material Type | Production Capacity (units/hour) | Energy Consumption (kWh) |

|---|---|---|---|---|

| 2000mm x 1500mm x 2500mm | 800 | Polyethylene Foam | 50 | 15 |

| 2500mm x 2000mm x 3000mm | 1200 | EVA Foam | 70 | 20 |

| 3000mm x 2500mm x 3500mm | 1500 | Memory Foam | 100 | 30 |

| 1500mm x 1000mm x 2000mm | 700 | Polyurethane Foam | 40 | 10 |

| 1800mm x 1400mm x 2200mm | 900 | Latex Foam | 60 | 18 |

Related Products