Top China Manufacturer of Popcorn Packaging Equipment for Your Business

When I first explored options for popcorn packaging equipment, I was amazed by the wide range of choices available from manufacturers in China. The equipment I found not only enhances production efficiency but also ensures that every kernel is perfectly packaged for freshness. I appreciate how these machines are designed to accommodate various bag sizes and styles, making them ideal for our diverse product lines. From my experience, the quality of the machinery is impressive, and the advanced technology helps optimize our workflow while reducing waste. Working with a dependable manufacturer in China means we can easily obtain replacement parts and technical support, ensuring minimal downtime for our operations. Plus, the pricing was very competitive, which is crucial for maintaining our bottom line. If you're in the market for reliable popcorn packaging equipment, I highly recommend considering options from China—you won’t be disappointed!

Popcorn Packaging Equipment Industry Giant Sets the Industry Standard

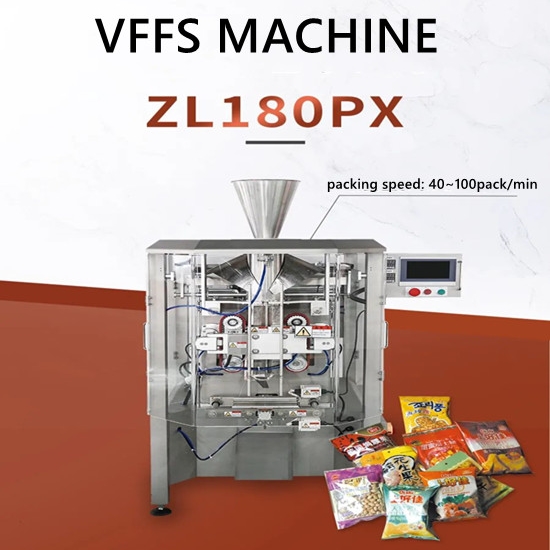

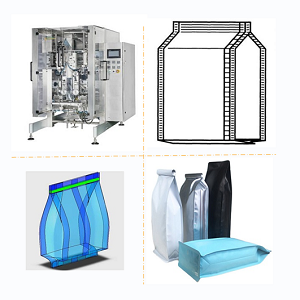

In the dynamic world of food production, popcorn has emerged as a beloved snack globally, and the demand for efficient, reliable packaging equipment has surged accordingly. Industry leaders are continuously innovating to set new benchmarks for quality and performance. The latest advancements in popcorn packaging technology emphasize automation, efficiency, and flexibility, catering to a diverse array of customer needs. With state-of-the-art machinery designed for high-speed packaging, companies can streamline their production processes while maintaining the pristine quality of their product. Sustainable practices are also at the forefront of industry developments, with eco-friendly packaging solutions gaining popularity among consumers and manufacturers alike. This shift not only meets the growing demand for environmentally responsible products but also enhances brand reputation. As companies strive to meet international standards, investing in cutting-edge machinery can significantly impact their competitive edge in the marketplace. For global buyers, partnering with leading manufacturers means accessing not only top-tier equipment but also a wealth of industry expertise. When selecting a packaging solution, it’s vital to consider factors such as the equipment's adaptability to varied production requirements, ease of maintenance, and long-term performance reliability. As the popcorn packaging equipment sector continues to evolve, staying informed about the latest innovations will help businesses make strategic purchasing decisions capable of driving growth and enhancing customer satisfaction.

| Equipment Type | Capacity (kg/h) | Speed (bags/min) | Power Consumption (kW) | Dimensions (LxWxH mm) |

|---|---|---|---|---|

| Vertical Form Fill Seal | 100 | 35 | 2.5 | 2000 x 1200 x 1800 |

| Pillow Packing Machine | 150 | 40 | 3.0 | 2500 x 1300 x 1900 |

| Flow Wrapper | 120 | 45 | 2.0 | 2100 x 1150 x 1600 |

| Auto Bagging Machine | 80 | 30 | 2.2 | 1800 x 1100 x 1500 |

| Sealing Machine | 200 | 50 | 1.8 | 2200 x 1250 x 1750 |

Related Products