Top Wire Wrapping Machinery Manufacturer in China for Optimal Performance

Are you in need of high-quality wire wrapping machinery? I specialize in top-notch equipment that meets the demands of various industries. Sourced directly from reliable manufacturers in China, my products combine durability and efficiency to streamline your production processes. Whether you're in electronics, telecommunications, or automotive sectors, our wire wrapping machines can significantly enhance your operation while ensuring precision. I focus on providing solutions that cater to your specific needs, so you can trust that you're receiving the very best in technology and performance. With my experience in collaborating with reputable manufacturers, I can guarantee competitive pricing and excellent customer support. Don't miss out on the opportunity to elevate your business with the right machinery. Get in touch today, and let's discuss how my wire wrapping solutions can help you achieve your production goals!

Wire Wrapping Machinery Dominates From Concept to Delivery

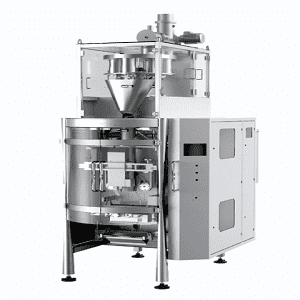

Wire wrapping machinery has become a cornerstone in modern manufacturing, seamlessly integrating innovative technology from concept to delivery. The rise of automation in wire harness production has enabled manufacturers to increase efficiency and ensure precision in every application. With the ability to handle various wire types and sizes, these machines offer unparalleled versatility, making them essential for industries ranging from electronics to automotive. In today’s competitive market, global procurement specialists seek solutions that not only enhance production capabilities but also reduce operational costs. Investing in advanced wire wrapping machinery means securing a reliable production line capable of meeting diverse demands while minimizing downtime. Automated features, like programmable logic controllers and real-time monitoring systems, empower businesses to maintain optimal performance, ensuring quality and compliance throughout the manufacturing process. Moreover, the focus on sustainability and eco-friendly practices underscores the importance of state-of-the-art machinery that minimizes waste and energy consumption. By choosing the right wire wrapping technology, companies can align their operations with global sustainability goals, offering greener solutions to their customers. As the industry continues to evolve, staying ahead of the curve with cutting-edge machinery will be pivotal for businesses looking to thrive in a dynamic marketplace.

Wire Wrapping Machinery Dominates From Concept to Delivery

| Dimension | Description | Materials Used | Application | Delivery Time |

|---|---|---|---|---|

| Compact | Ideal for small-scale operations. | Aluminum, Copper | Wiring for electronics | 2 weeks |

| Industrial | High efficiency for large operations. | Steel, Copper | Automotive wiring | 1 month |

| Portable | Designed for on-site work. | Plastic, Copper | Field services | 3 weeks |

| Automated | Fully automated production line. | Various alloys | Mass production | 6 weeks |

Related Products