Automatic Oil Packaging Machine Manufacturer in China - Quality Solutions

As a business owner in need of efficient packaging solutions, I understand the importance of reliability in production. That's why I turned to the Automatic Oil Packaging Machine, a top-tier choice for manufacturers like us in China. It’s designed specifically to streamline the oil packaging process, allowing for high-speed filling while maintaining precision. This machine isn’t just about speed; it’s built to handle different oil types, adapt to various bottle sizes, and ensure minimal wastage. I've noticed significant improvements in production efficiency since integrating it into my operations. Working directly with a reputable Chinese manufacturer means I can count on quality and support throughout the process. Whether I’m dealing with large-scale production or smaller batches, this packaging machine meets my needs perfectly. Join me in enhancing your production line with this automatic solution, and experience the benefits firsthand!

Automatic Oil Packaging Machine Leads the Global Market Service Backed by Expertise

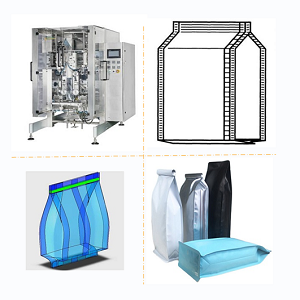

In today's fast-paced manufacturing world, efficiency and precision are paramount, particularly in the oil packaging sector. The automatic oil packaging machine stands out as a game-changer in this landscape, providing solutions that not only enhance productivity but also ensure consistency and quality. As global demand for packaged oils continues to rise, businesses are seeking innovative machinery that can adapt to diverse packaging needs, from small-scale operations to large industrial processors. The essence of a leading automatic oil packaging machine lies in its design and functionality. Equipped with cutting-edge technology, these machines offer features such as automated filling, sealing, and labeling, thus reducing labor costs and minimizing human error. Manufacturers can benefit from customizable settings that allow for adjustments based on product viscosity and packaging size, ensuring that every batch meets the highest standards. Furthermore, the integration of smart technologies enables real-time monitoring and data collection, empowering businesses to optimize their operations and maintain competitive advantages. Support and expertise from experienced professionals in machinery design and operation significantly enhance the value proposition of these packaging solutions. Alongside durable machinery, access to comprehensive training, maintenance, and after-sales support ensures that businesses can maximize their investment. As the global market continues to evolve, companies that embrace advanced packaging technologies stand to gain not only in efficiency but also in sustainability, as automated systems often lead to reduced waste and energy consumption. By investing in top-notch automatic oil packaging machines, businesses position themselves at the forefront of the industry, ready to meet the needs of a dynamic marketplace.

Automatic Oil Packaging Machine Leads the Global Market Service Backed by Expertise

| Feature | Specification | Market Share (%) | Key Regions |

|---|---|---|---|

| Speed | 20-50 bottles/min | 25% | North America, Europe |

| Automation Level | Fully Automatic | 30% | Asia Pacific |

| Material Type | Plastic, Glass | 18% | South America, Middle East |

| Operating Power | 3-5 kW | 15% | Africa, Oceania |

| Dimensions (L x W x H) | 1500 x 800 x 2000 mm | 12% | Global |

Related Products