Best-Selling Mesh Bag Packaging Machine - AUTOMATIC FOOD PACKING MACHINERY FOR BISCUIT CAKE COOKIES CHOCOLATE BAR – Soontrue

Product Detail

Video Information

Related Video

Feedback (2)

Best-Selling Mesh Bag Packaging Machine - AUTOMATIC FOOD PACKING MACHINERY FOR BISCUIT CAKE COOKIES CHOCOLATE BAR – Soontrue Detail:

| Model: | ZL230 |

| Bag size | L 80mm-300mm |

| W 80mm-200mm | |

| Suitable film width | 130mm-320mm |

| Packing speed | 15-70 bags/min |

| Packing film | Laminated film |

| Power supply | 220V 50HZ, 1PH |

| Compress air consuming | 6kg/cm² 250L/min |

| Machine noise | ≤75db |

| General power | 4.0kw |

| Weight | 650kg |

| Outer dimension | 1770mm*1105mm*1500mm |

1. The whole machine use 3 servo control system, running stability, high accuracy, fast speed, lower noisy.

2. It adopt touch screen operate, more easy, more intelligent.

3.Various packing type: pillow bag, punch hole bag, connect bags etc.

4. This machine can equip with multi-head weigher , electrical weigher, volume cup etc.

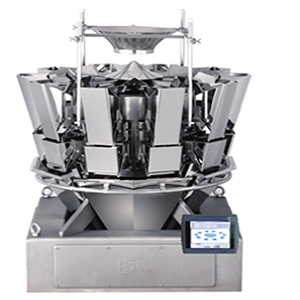

10 HEADS WEIGHER

● Features

1. One of the most economic&stable multi-head weigher in the world the best cost-effective

2. Stagger Dump avoid bigger items pile up

3. Individual feeder control

4. User friendly touch screen equipped with multiple language

5. Compatible with single packaging machine, rotary bagger, cup/bottle machine, tray sealer etc.

6. 99 preset program for multiple tasks.

| Item | Standard 10 multi heads weigher |

| Generation | 2.5G |

| Weighing range | 15-2000g |

| Accuracy | ±0.5-2g |

| Max speed | 60WPM |

| Power supply | 220V , 50HZ, 1.5KW |

| Hopper volume | 1.6L/2.5L |

| Monitor | 10.4 inches color touch screen |

| Dimension (mm) | 1436*1086*1258 |

| 1436*1086*1388 |

Z-TYPE CONVEYOR

● Features

The conveyer is applicable for vertical lifting of grain material in departments such as corn, food, fodder and chemical industry, etc. For the lifting machine,

the hopper is driven by the chains to lift. It’s used for vertical feeding of grain or small block material. It has advantages of large lifting quantity and highness.

● Specification

| Model | ZL-3200 HD |

| Bucket hopper | 1.5 L |

| Capacity(m³h) | 2-5 m³h |

| Bucket material | PP Food Gradewe have developed dozens of bucket molds ourselves |

| Bucket style | Slippy bucket |

| Framework material | Sprocket: Mild steel with chrome coatingAxis: Mild steel with nickel coating |

| Dimension | Machine height 3100*1300 mmStandard export case 1.9*1.3*0.95 |

| Optional parts | Frequency converterSensorPan for leakage product |

| The material and brand of the internal parts of the machine can be specified , and it can be be selected according to the product and service environment of the machine | |

Z-TYPE CONVEYOR

● Features

The supporting platform is solid will not affect the measurement accuracy of the combination weigher.

In addition, the table board is to use the dimple plate, it is more secure, and it can avoid slipping.

● Specification

The size of the supporting platform is according to the type of the machines.

● Features

The machine can send the packed finished bag to after-package detecting device or packing platform.

● Specification

| Lifting height | 0.6m-0.8m |

| Lifting capacity | 1 cmb/hour |

| Feeding speed | 30mminute |

| Dimension | 2110×340×500mm |

| Voltage | 220V/45W |

OUTPUT CONVEYOR

Product detail pictures:

Related Product Guide:

Lego to launch sustainable bricks made from sugar cane | Sugar Packing Machine

Global Packaging Machinery Markets, 2016-2018 & 2024: Industry 4.0 | Automatic Blister Packing Machine

Our corporation insists all along the quality policy of "product top quality is base of organization survival; purchaser pleasure will be the staring point and ending of an company; persistent improvement is eternal pursuit of staff" plus the consistent purpose of "reputation very first, purchaser first" for Best-Selling Mesh Bag Packaging Machine - AUTOMATIC FOOD PACKING MACHINERY FOR BISCUIT CAKE COOKIES CHOCOLATE BAR – Soontrue, The product will supply to all over the world, such as: kazan, Tunisia, Algeria, Our company has already have pass the ISO standard and we're fully respect our customer 's patents and copyrights. If the customer provides their own designs, We will guarantee that they will likely be the only one can have that merchandise. We hoping that with our good products can bring our customers a great fortune.

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.

Send your message to us:

RELATED PRODUCTS

-

High Performance Full Automatic Food Packing Ma...

-

professional factory for Food Packaging Machine...

-

Cheapest Factory Automatic Rice Packing Machine...

-

Factory Outlets India Wheat Flour Packing Machi...

-

Chinese wholesale 25 Kg Powder Packing Machine ...

-

High Performance Cacao Weighing Packaging Machi...