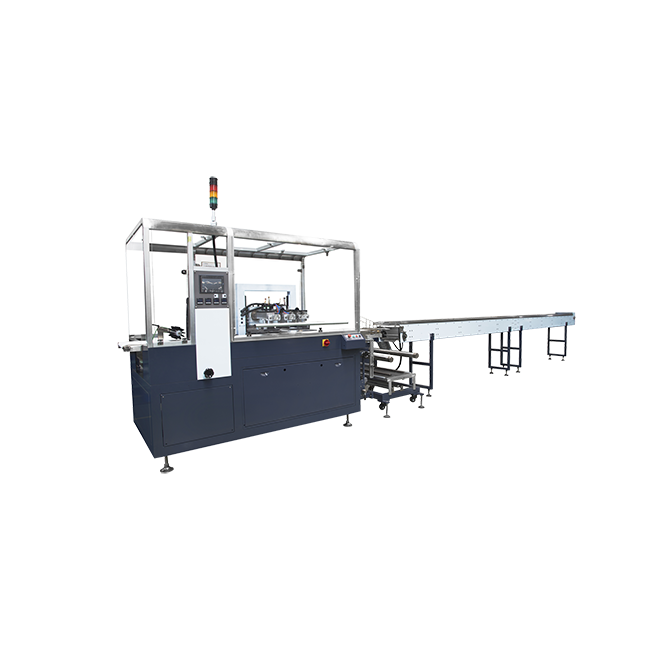

China Manufacturer for Chocolate Bar Packing Machine - Milk Powder Vertical Packing Machine – Soontrue – Soontrue

Product Detail

Video Information

Related Video

Feedback (2)

China Manufacturer for Chocolate Bar Packing Machine - Milk Powder Vertical Packing Machine – Soontrue – Soontrue Detail:

It is suitable for automatic packaging of granular strip, sheet, block, ball shape, powder and other products. Such as snack, chips, popcorn, puffed food,dried fruits, cookies, biscuits, candies, nuts, rice,beans, grains, sugar, salt, pet food, pasta, sunflower seeds, gummy candies, lollipop, Sesame.

1 .The whole machine adopts uniaxial or biaxial servo control system, which can choose two kinds of servo single film pulling and double film pulling structure according to the different characteristics of packing material and can choose vacuum adsorption pull film system;

2. Horizontal sealing system can be pneumatic drive system or servo drive system, to meet the diverse needs of different users;

3. Various packing format:pillow bag, side ironing bag, gusset bag, triangle bag, punching bag, continuous bag type;

4. It can be combined with the multi-head weigher, auger scale, volume cup system and other measuring equipment, accurate and measurement;

5. The design of the whole machine conforms to GMP standard and has passed CE certification

Auger Lifter:

Parameters:

| Model | CL100K |

| Charging Capacity | 12m³/h |

| Diameter of Pipe | Φ219 |

| Total Power | 4.03kW |

| Total Weight | 270kg |

| Hopper Volume | 200L |

| Power Supply | 3P AC208V-415V 53/60Hz |

| Lifting Angle | Standard 45°, Customized 30~60° |

| Lifting Height | Standard 1.85m, Customized 1~5m |

Auger Lifter:

Parameters:

| Model | CL100K |

| Charging Capacity | 12m³/h |

| Diameter of Pipe | Φ219 |

| Total Power | 4.03kW |

| Total Weight | 270kg |

| Hopper Volume | 200L |

| Power Supply | 3P AC208V-415V 53/60Hz |

| Lifting Angle | Standard 45°, Customized 30~60° |

| Lifting Height | Standard 1.85m, Customized 1~5m |

SUPPORTING PLATFORM

● Features

The supporting platform is solid will not affect the measurement accuracy of the combination weigher.

In addition, the table board is to use the dimple plate, it is more secure, and it can avoid slipping.

● Specification

The size of the supporting platform is according to the type of the machines.

Out Conveyor

● Features

The machine can send the packed finished bag to after-package detecting device or packing platform.

● Specification

| Lifting height | 0.6m-0.8m |

| Lifting capacity | 1 cmb/hour |

| Feeding speed | 30mminute |

| Dimension | 2110×340×500mm |

| Voltage | 220V/45W |

Product detail pictures:

Related Product Guide:

By Chloe is a growing vegan fast food chain: photos, details | Automatic Powder Packing Machine

Global Multifunction Packing MachineMarket Insight Report 2018-2025- M.J.Maillis, Lantech, Robopac, TAM, ARPAC, Reiser, Muller, Orion | Lentil Packing Machine Price

Our advancement depends on the superior gear ,superb talents and consistently strengthened technology forces for China Manufacturer for Chocolate Bar Packing Machine - Milk Powder Vertical Packing Machine – Soontrue – Soontrue, The product will supply to all over the world, such as: Kazakhstan, Thailand, Karachi, our qualify products have good reputation from the world as its most competive price and our most advantage of after-sale service to the clients.we hope we can provide a safe, environmental products and super service to our clients from all of the world and establish strategic partnership with them by our professional standards and unremitting efforts.

Products and services are very good, our leader is very satisfied with this procurement, it is better than we expected,

Send your message to us:

RELATED PRODUCTS

-

Cheap price Double Weigher Corn Packing Machine...

-

Personlized Products Saline Bag Filling Machine...

-

Personlized Products Automatic Packaging Machin...

-

Ordinary Discount Thermo Shrink Packaging Machi...

-

18 Years Factory Electric Food Vacuum Packaging...

-

Best quality Petg Jar Packing Boxes Making Mach...