Factory Outlets Given Bag Filling Packing Machine - PREMADE ZIPPER BAG STAND UP POUCH DOYBAG COFFEE BEAN PACKING MACHINE – Soontrue

Product Detail

Video Information

Related Video

Feedback (2)

Factory Outlets Given Bag Filling Packing Machine - PREMADE ZIPPER BAG STAND UP POUCH DOYBAG COFFEE BEAN PACKING MACHINE – Soontrue Detail:

| Model: | GDR-100F |

| Packing speed | 6-65bags/min |

| Bag size | L120-360mm W130-250mm |

| Packing format | Bags (flat bag, stand bag, hand bag, M bag etc irregular bags) |

| Power supply | 380V, 50Hz |

| General power | 3.5kw |

| Air consumption | 5-7kg/cm² 500L/min |

| Packing material | Single layer PE, PE complex film etc |

| Machine weight | 1000kg |

| Outside dimensions | 2200mm*1400mm*1600mm |

1. The machine with ten-station structure, running by PLC, big touch screen centralized control, easy operation;

2. Automatic fault tracking and alarm system;

3. Mechanical empty bag tracking and detection device, to achieve no bag opening, no filling and no sealing;

4. The main drive system adopts variable frequency speed control, full CAM drive, running smoothly, low failure rate;

5 The design of the whole machine conforms to GMP standard and has passed CE certification.

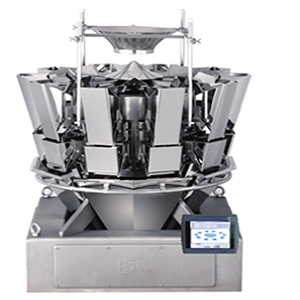

10 HEADS WEIGHER

● Features

1. One of the most economic&stable multi-head weigher in the world the best cost-effective

2. Stagger Dump avoid bigger items pile up

3. Individual feeder control

4. User friendly touch screen equipped with multiple language

5. Compatible with single packaging machine, rotary bagger, cup/bottle machine, tray sealer etc.

6. 99 preset program for multiple tasks.

| Item | Standard 10 multi head weigher |

| Generation | 2.5G |

| Weighing range | 15-2000g |

| Accuracy | ±0.5-2g |

| Max speed | 60WPM |

| Power supply | 220V , 50HZ, 1.5KW |

| Hopper volume | 1.6L/2.5L |

| Monitor | 10.4 inches color touch screen |

| Dimension (mm) | 1436*1086*1258 |

| 1436*1086*1388 |

Z-TYPE CONVEYOR

● Features

The conveyer is applicable for vertical lifting of grain material in departments such as corn, food, fodder and chemical industry, etc. For the lifting machine,

the hopper is driven by the chains to lift. It’s used for vertical feeding of grain or small block material. It has advantages of large lifting quantity and highness.

● Specification

| Model | ZL-3200 HD |

| Bucket hopper | 1.5 L |

| Capacity(m³h) | 2-5 m³h |

| Bucket material | PP Food Gradewe have developed dozens of bucket molds ourselves |

| Bucket style | Slippy bucket |

| Framework material | Sprocket: Mild steel with chrome coatingAxis: Mild steel with nickel coating |

| Dimension | Machine height 3100*1300 mmStandard export case 1.9*1.3*0.95 |

| Optional parts | Frequency converterSensorPan for leakage product |

| The material and brand of the internal parts of the machine can be specified , and it can be be selected according to the product and service environment of the machine | |

SUPPORTING PLATFORM

● Features

The supporting platform is solid will not affect the measurement accuracy of the combination weigher.

In addition, the table board is to use the dimple plate, it is more secure, and it can avoid slipping.

● Specification

The size of the supporting platform is according to the type of the machines.

● Features

The machine can send the packed finished bag to after-package detecting device or packing platform.

● Specification

| Lifting height | 0.6m-0.8m |

| Lifting capacity | 1 cmb/hour |

| Feeding speed | 30mminute |

| Dimension | 2110×340×500mm |

| Voltage | 220V/45W |

Product detail pictures:

Related Product Guide:

The âQuestâ for a fun and tasty brand identity | Automatic Blister Packing Machine

Packaging for low-sugar product line emphasizes sweet taste | Lentil Packing Machine Price

We attempt for excellence, company the customers", hopes to be the top cooperation team and dominator company for personnel, suppliers and customers, realizes price share and continual marketing for Factory Outlets Given Bag Filling Packing Machine - PREMADE ZIPPER BAG STAND UP POUCH DOYBAG COFFEE BEAN PACKING MACHINE – Soontrue, The product will supply to all over the world, such as: Rio de Janeiro, Danish, United Arab emirates, Based on products and solutions with high quality, competitive price, and our full range service, we have accumulated experienced strength and experience, and we've built up a very good reputation in the field. Along with the continuous development, we commit ourselves not only to the Chinese domestic business but also the international market. May you moved by our high quality items and passionate service. Let's open a new chapter of mutual benefit and double win.

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.

Send your message to us:

RELATED PRODUCTS

-

Factory Cheap Honey Packing Machine - SZ180 Ho...

-

Factory supplied Rotary Pouch Packing Machine -...

-

Best-Selling Mini Pouch Packing Machine - ZL18...

-

Wholesale Price Anti Static Cellulose Tape - H...

-

Lowest Price for Pillow Packing Machine Price -...

-

Factory selling Packaging Machine For Powders -...