Newly Arrival Multi-Function Bag Packing Machine Liquid – CASHEW NUTS/WALNUTS WEIGHING FILLING CAPPING MACHINE AUTOMATIC PLASTIC BOTTLE FILLING AND CAPPING MACHINE – Soontrue

Product Detail

Video Information

Related Video

Feedback (2)

Newly Arrival Multi-Function Bag Packing Machine Liquid – CASHEW NUTS/WALNUTS WEIGHING FILLING CAPPING MACHINE AUTOMATIC PLASTIC BOTTLE FILLING AND CAPPING MACHINE – Soontrue Detail:

| Model: | GPR80 |

| Average speed | 30-45cans/min |

| Height | 80-200mm |

| Diameter | 60-140mm |

| Compressed air quantity | L5-7kgcm² 500L/min |

| Packing material | Jars |

| Machine gross | 1000kg |

| Power type | 220V 200W 50HZ |

| Out-dimension | 2100*1280*1600mm |

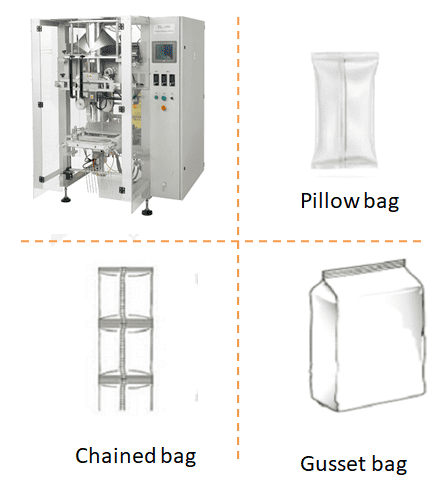

1. The whole machine adopts double servo control system, can based on different product and film material to choose different servo film pulling structure. Can equip with vacuum absorb film system;

2. Horizontal sealing servo control system can realize automatic setting and adjustment of horizontal sealing pressure;

3. Various packing format:pillow bag, side ironing bag, gusset bag, triangle bag, punching bag, continuous bag type;

4. It can be combined with the multi-head weigher, auger scale, volume cup system and other measuring equipment, accurate and measurement;

5. The design of the whole machine conforms to GMP standard and has passed CE certification

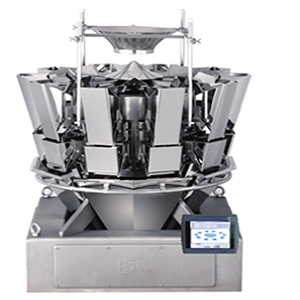

10 HEADS WEIGHER

● Features

1. One of the most economic&stable multi-head weigher in the world the best cost-effective

2. Stagger Dump avoid bigger items pile up

3. Individual feeder control

4. User friendly touch screen equipped with multiple language

5. Compatible with single packaging machine, rotary bagger, cup/bottle machine, tray sealer etc.

6. 99 preset program for multiple tasks.

| Item | Standard 10 multi head weigher |

| Generation | 2.5G |

| Weighing range | 15-2000g |

| Accuracy | ±0.5-2g |

| Max speed | 60WPM |

| Power supply | 220V , 50HZ, 1.5KW |

| Hopper volume | 1.6L/2.5L |

| Monitor | 10.4 inches color touch screen |

| Dimension (mm) | 1436*1086*1258 |

| 1436*1086*1388 |

Z-TYPE CONVEYOR

● Features

The conveyer is applicable for vertical lifting of grain material in departments such as corn, food, fodder and chemical industry, etc. For the lifting machine,

the hopper is driven by the chains to lift. It’s used for vertical feeding of grain or small block material. It has advantages of large lifting quantity and highness.

● Specification

| Model | ZL-3200 HD |

| Bucket hopper | 1.5 L |

| Capacity(m³h) | 2-5 m³h |

| Bucket material | PP Food Gradewe have developed dozens of bucket molds ourselves |

| Bucket style | Slippy bucket |

| Framework material | Sprocket: Mild steel with chrome coatingAxis: Mild steel with nickel coating |

| Dimension | Machine height 3100*1300 mmStandard export case 1.9*1.3*0.95 |

| Optional parts | Frequency converterSensorPan for leakage product |

| The material and brand of the internal parts of the machine can be specified , and it can be be selected according to the product and service environment of the machine | |

SUPPORTING PLATFORM

● Features

The supporting platform is solid will not affect the measurement accuracy of the combination weigher.

In addition, the table board is to use the dimple plate, it is more secure, and it can avoid slipping.

● Specification

The size of the supporting platform is according to the type of the machines.

● Features

The machine can send the packed finished bag to after-package detecting device or packing platform.

● Specification

| Lifting height | 0.6m-0.8m |

| Lifting capacity | 1 cmb/hour |

| Feeding speed | 30mminute |

| Dimension | 2110×340×500mm |

| Voltage | 220V/45W |

Product detail pictures:

Related Product Guide:

SP Thermoforming: Carousel-Designed Thermoforming Machines | Automatic Powder Packing Machine

Preparing for an Automated Future | 2018-08-23 | Automatic Blister Packing Machine

With our loaded encounter and considerate services, we have now been recognized as a trustworthy supplier for lots of worldwide consumers for Newly Arrival Multi-Function Bag Packing Machine Liquid – CASHEW NUTS/WALNUTS WEIGHING FILLING CAPPING MACHINE AUTOMATIC PLASTIC BOTTLE FILLING AND CAPPING MACHINE – Soontrue, The product will supply to all over the world, such as: Honduras, Saudi Arabia, Juventus, We guarantee that our company will try our best to reduce customer purchase cost , shorten the period of purchase , stable merchandise quality , increase customers' satisfaction and achieve win-win situation .

This supplier offers high quality but low price products, it is really a nice manufacturer and business partner.

Send your message to us:

RELATED PRODUCTS

-

New Fashion Design for Herb Packing Machine - ...

-

Factory Outlets Precipitated Silica Powder - P...

-

Factory For Automatic Coffee Pods Packing Machi...

-

Best Price for Pillow Pouch Packaging Machine -...

-

Factory Free sample Carton Boxes Cosmetic - LX...

-

Factory Free sample Baby Food Packaging Machine...