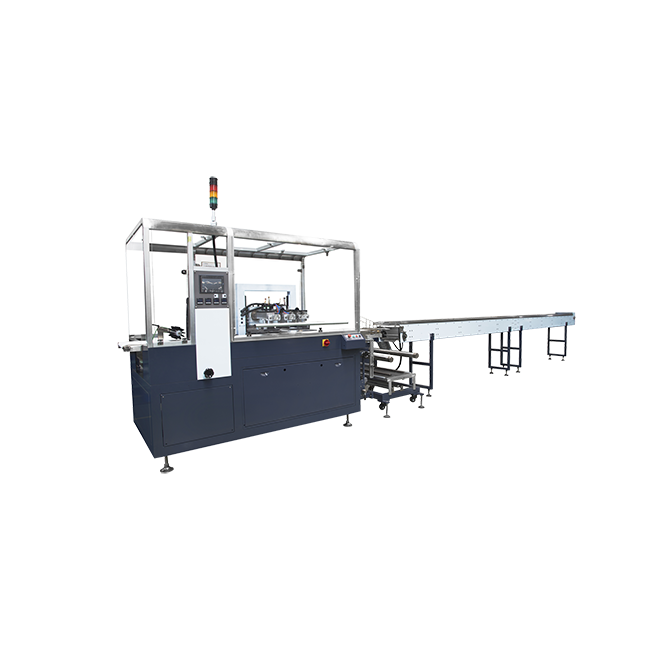

Professional China Popsicle Production Line - DLS06 – Soontrue

Product Detail

Video Information

Related Video

Feedback (2)

Professional China Popsicle Production Line - DLS06 – Soontrue Detail:

Main characteristics & Structure features:

1. The servo control system is used for raising and lowering the horizontal sealing bar, which improves packing capacity, and enables easy change of the bag length by simply setting numeric data.

2. The weighing-table is controlled by servo motor, which a small synchronous adjustment can be performed by simply setting numeric data.

3. Product data memory function is used for simple operation. When changing product sizes, the bag length can be easily changed by setting product serial number.

4. Combined with finished products managing device, cartooning machine can form the complete production line.

5. Coordinated with many measuring and filling devices such as auger and volumetric cup filling device for accurate measurement.

Product detail pictures:

Related Product Guide:

Tomorrow’s World: Pack to the Future | Lentil Packing Machine Price

China Medicine Packaging Machines Market Analysis 2023: Impressively Growing Latest Technology Trends With Top Manufactures And Business Opportunities | Sugar Packing Machine

Adhering to the principle of "quality, service, efficiency and growth", we have gained trusts and praises from domestic and international client for Professional China Popsicle Production Line - DLS06 – Soontrue, The product will supply to all over the world, such as: Bangalore, Greek, Orlando, Our staffs are adhering to the "Integrity-based and Interactive Development" spirit, and the tenet of "First-class Quality with Excellent Service". According to the needs of every customer, we provide customized & personalized services to help customers achieve their goals successfully. Welcome clients from home and abroad to call and inquire!

The product classification is very detailed that can be very accurate to meet our demand, a professional wholesaler.