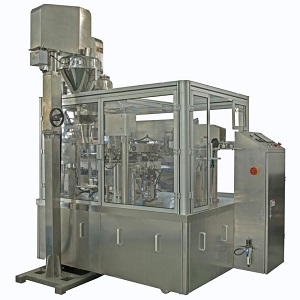

Reasonable price Ink Filling Machine - AUTOMATIC PAPER BAG PACKING AUGER POWDER PACKAGING MACHINE FOR TEA/COFFEE /MILK – Soontrue

Product Detail

Video Information

Related Video

Feedback (2)

Reasonable price Ink Filling Machine - AUTOMATIC PAPER BAG PACKING AUGER POWDER PACKAGING MACHINE FOR TEA/COFFEE /MILK – Soontrue Detail:

It is suitable for automatic packaging of granular strip, sheet, block, ball shape, powder and other products. Such as snack, chips, popcorn, puffed food,dried fruits, cookies, biscuits, candies, nuts, rice,beans, grains, sugar, salt, pet food, pasta, sunflower seeds, gummy candies, lollipop, Sesame.

1 The whole machine is a ten-station structure, and its operation is controlled by PLC and large-screen touch screen, so it is easy and convenient to operate

2 Automatic fault tracking and alarm system, real-time display of operation status;

3 Mechanical empty bag tracking and detecting device can realize no bag opening, no blanking and no sealing;

4The main drive system adopts variable frequency stepless speed regulation control and full CAM drive, with stable operation and low failure rate (the sealing adopts CAM drive, which will not lead to unqualified sealing due to unstable air pressure);

5 Replacement of product specifications with a key replacement, better improve work efficiency.

6The parts of the machine that come into contact with materials or packaging bags are processed with stainless steel or other materials that meet the requirements of food hygiene to ensure the hygiene and safety of food.

7With liquid mixing device, to prevent the precipitation of micro - particle materials, with liquid level control device.

8The whole machine design conforms to the national GMP standard and has passed the CE certification

Auger scale

● Feature

This type can do dosing and filling work. Due to the special professional design, it is suitable for the fluidity or low-fluidity materials, like milk powder, Albumen powder, rice powder, coffee powder, solid drink, condiment, white sugar, dextrose, food additive, fodder, pharmaceuticals, agriculture pesticide, and so on.

|

Hopper |

Split hopper 25L |

|

Packing Weight |

1 - 200g |

|

Packing Weight |

≤ 100g, ≤±2%; 100 – 200g, ≤±1% |

|

Filling speed |

1- 120 次/分钟,40 – 120 times per min |

|

Power supply |

3P AC208-415V 50/60Hz |

|

Total Power |

1.2 Kw |

|

Total Weight |

140kg |

|

Overall Dimensions |

648×506×1025mm |

Auger lifter

| Speed |

3m3/h |

| Feeding pipe diameter |

Φ114 |

| Machine power |

0.78W |

| Machine weight |

130kg |

| Material box volume |

200L |

| Material box of voulme |

1.5mm |

| Round tube wall thickness |

2.0mm |

| Spiral diameter |

Φ100mm |

| Pitch |

80mm |

| Blade thickness |

2mm |

| Shaft diameter |

Φ32mm |

| Shaft wall thickness |

3mm |

● Features

The machine can send the packed finished bag to after-package detecting device or packing platform.

● Specification

| Lifting height | 0.6m-0.8m |

| Lifting capacity | 1 cmb/hour |

| Feeding speed | 30mminute |

| Dimension | 2110×340×500mm |

| Voltage | 220V/45W |

Product detail pictures:

Related Product Guide:

Packing a better meal for the trail | Automatic Blister Packing Machine

Celebrity chef Maggie Beer shares secret to perfect chicken soup | Sugar Packing Machine

Always customer-oriented, and it's our ultimate goal to get not only by far the most reputable, trustable and honest supplier, but also the partner for our customers for Reasonable price Ink Filling Machine - AUTOMATIC PAPER BAG PACKING AUGER POWDER PACKAGING MACHINE FOR TEA/COFFEE /MILK – Soontrue, The product will supply to all over the world, such as: United States, Bangkok, Portugal, We always stick to the tenet of "sincerity, high quality, high efficiency, innovation". With years of efforts, we have established friendly and stable business relationships with worldwide customers. We welcome any of your inquiries and concerns for our products, and we are sure that we will offer just what you want, as we always believe that your satisfaction is our success.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!

Send your message to us:

RELATED PRODUCTS

-

China New Product Sachets Filling Machine - S...

-

Big discounting High Stability Card Packaging M...

-

Factory best selling Powder Sachet Packing Mach...

-

Cheapest Factory Energy 3 In 1 Drink Packaging ...

-

New Arrival China Big Bag Automatic Packing Mac...

-

Special Design for Auger Filler For Packing Mac...